Download PDF Version

Operating and maintenance instructions.

The liquid level switches work on the principle of reed switches activated by a permanent magnet inside the float.

The reed switches are rated for use at 32 V AC/DC 500mA (Larger voltages available as special order)

The reed switch is located inside the tube in a fixed position and the movement of the float changes the location of the magnetic field and the contacts of the reed switch are closed or opened.

The operation of the reed switch can be checked by using the continuity function of the multi meter.

There are no serviceable components and any repairs should be returned to the manufacturer.

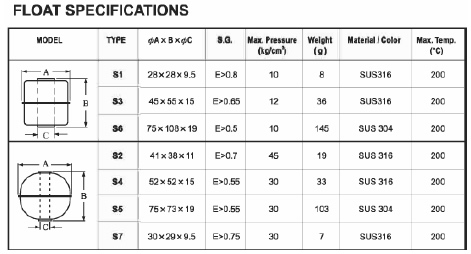

The appropriate float should be selected to ensure that the float will work in the liquids specific gravity, your float should not have a specific gravity rating higher than or equal to the liquid.

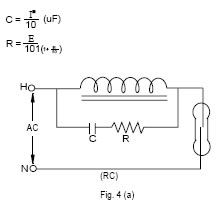

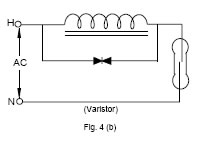

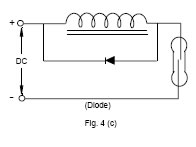

The attached sheet details what protection should be used when switching other than resistive loads.

|

INDUCTIVE LOADS

When using reed switches for inductive loads such as motors, relay coil, solenoids, etc., the contacts

will be subjected to high induced voltages during opening of the contacts (load circuit). Such high induced voltages (transients) may cause damage to the reed switch or significantly reduce its life. Therefore, protective circuits such as: RC (snubber), varistor or clamping diodes are recommended. (see Fig.4a, Fig.4b, Fig.4c)

* It is prohibited to drive directly solenoid valve, motor or magnetic switch.

|

|

|

|

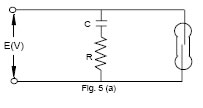

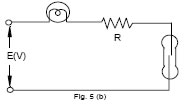

| When using reed switches for capacitive loads such as capacitors, incandescent lamps or long cables, The contacts will be subjects to high surge (inrush) current. |

Therefore, protective circuits such as: surge suppressors or current limiting resistors are recommended. (Fig. 5a, Fig. 5b) |

|

|